Carbon Steel WCA-Casting Material

Carbon Steel WCA in ASTM A216 for casting purpose

Casting Technology, include casting methods, casting material and casting standards.

Carbon Steel WCA in ASTM A216 for casting purpose

ASTM A216 Grade WCB carbon steel for casting purpose, chemistry and mechanical property

Abrasion-Resistant Cast Iron ASTM A532 Class II type A Designation 12% Cr

Stainless Steel CF8 (SS304) in ASTM A743, ASTM A351 and ASTM A744

What is Green Sand Casting? Green Sand Casting is mainly differed with resin sand casting . The mould sand is taken from rivers, and then put some others in sand to increase their viscidity. Green sand is an aggregate of sand, bentonite clay, pulverized coal and water. Its principal use is in making molds for […]

Grey Iron Specifications DIN EN1561. Compare GG serires with EN-JL grades. this material is suitable to sand casting production. Grey Cast iron is a casting alloy, iron and carbon based, the latter element being present mainly in the form of lamellar graphite particles. The properties of grey cast iron depend on the form and distribution of […]

Stainless Steel include austenitic stainless steel martensitic stainless steel and ferric stainless steel. this material is suitalbe to sand casting and investment casting method. Austenitic steels have austenite as their primary phase

BS EN877 Cast iron pipes and fittings, their joints and accessories for the evacuation of water from building. Requirements, test methods and quality assurance This European Standard applies to cast iron pipeline components used for the construction of discharge systems for buildings and of drains, normally as gravity systems.

Grey Cast Iron (Gray iron) HT200, HT250, HT300, HT350 in Chinese Standard GB/T 9439

Carbon steel have a good content of carbon, so it is easy to casting. especially A216 WCB. It is important to clarify the meaning of carbon steel in the generic sense and in the more narrow context used in this report. The term steel is usually taken to mean an iron-based alloy containing carbon in […]

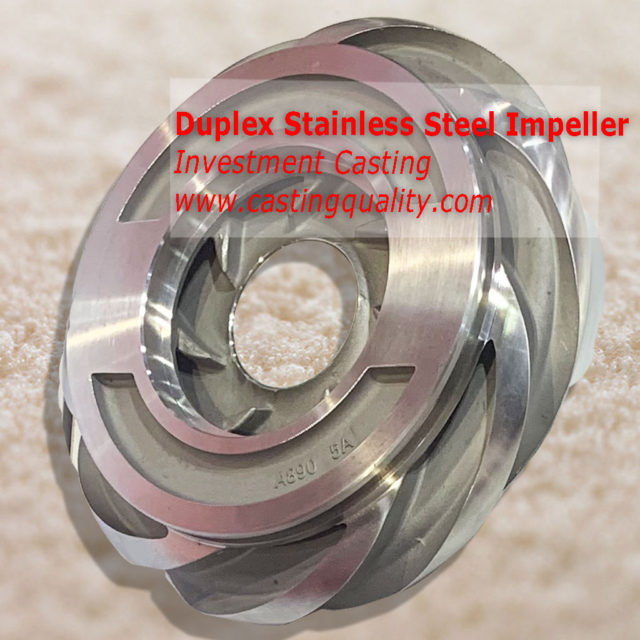

Duplex Stainless steel has two phase micro-structure consisting of grains of Ferritic and Austenitic stainless steel. It is mainly used in pump fittings and oil field. Casting Quality Industrial can produce SAF2205 DUPLEX STAINLESS STEEL castings.

Cast Iron is individed to four types: gray iron, ductile iron, malleable iron, vermicular cast iron, abrasion-resistant cast iron and corrosion resistant cast iron. Generally, we mainly use sand casting method to make iron castings, such as green sand casting, resin sand casting, Sodium silicate sand casting , lost foam casting and centrifugal casting. Gray […]

ASTM A995/A995M for Castings, Austenitic-Ferritic (Duplex) Stainless Steel

Duplex stainless steel castings, sorted by standard. Duplex Stainless steel has two phase microstructure consisting of grains of Ferritic and Austenitic stainless steel. It has a better strength and corrosion resistance property than stainless steel 304/316. Duplex stainless steels have lower nickel and molybdenum contents than their austenitic counterparts of similar corrosion resistance.

Castings — System of dimensional tolerances and machining allowances Mainly indicate the tolerance of castings, such as sand casting, investment casting, die casting and other casting method. Applies to cast metals and their alloys produced by various casting manufacturing processes. Is applicable both to general tolerances and/or required machining allowances

The Engineering and physical properties of cast iron wary with the type of iron; the designer must match the engineering requirements with al the properties of the specific type of cast iron being consiered. Machinability, e.g., is significantly affected by the type of cast iron specified. Gray cast iron is the most machinalbe; the white […]

Cast iron is classified in to fire basic types: each type is generally based on graphite morphology as following:Gray Iron

Ductile Iron

Malleable Iron

Compacted Graphite Iron

White Iron

A sand casting is also divided resin sand casting and green sand casting. sand casting is produced when molten metal is poured at atmospheric pressure into a cavity formed in a compacted molding sand. In typical ferrous casting, the mold would be bonded with 6 to 8 percent western bentonite mulled with 2 to 3 […]

The sand casting comprison in green sand casting, resin sand casting.Sodium silicate bonded sand casting and dry mould casting

Investment casting( precision casting, also named lost wax casting ) is an advanced metalforming process used to produce metal parts of the highest quality, functionality and cost-effectiveness. Investment casting( precision casting) is a one-to-one process in which one disposable pattern produces one metal part. When combined with modern production knowledge and technologies, Investment casting( precision casting) can be […]