Design Skill

As one professional supplier of castings in China, we help many clients to improve their products design. Our mechanical engineers have more than 10 years’ experience; they have been focused on Machinery and Casting design.

Anyway, if you have drawings/draft, or just one sample, we will return you a physical part.

•Products Design Improving.

Most design engineers don’t have experience about actual production, their design will be complicated in actual production, and the part will be very expensive too. When we get the design, we will analysis the possibility in production, and provide much proposal to make everything easy and convenient.

Our another job is to find a right process for design, some parts are suitable for sand casting, some for investment casting, but some parts will be machined from billet only.. SAVE MONEY AND SAVE COST, it’s our principle.

•Material Proposal.

If you just have sample part, we will analysis the chemistry to find a suitable metal grade.

If you just have an idea, we will recommend one good material based on your usage. We have more than 1000 standard documents such as ASTM, BS, ISO, DIN and so on.

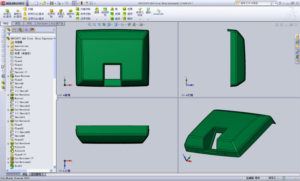

•Drawing and Simulation:

You can send us those types drawing:

DXF/DWG for Auto CAD;

IGS/STEP for Solid Works, Pro/E or U/G

PDF type is welcome too.

When we get your design, 3D model will be built in our computer to analysis the structure.

•Casting Technology Design

Our foundry engineer will advise some necessary modification for castings, maybe tolerance, maybe foundry daft, maybe hot pot or distortion risk. And we will design two or three pouring systems for trial production too. No any foundry can declare 100% good parts, but we have been trying our best to promote our service.

•Machining Technology Advice

We met many machining problems in past years, the drawings show very strictly tolerance for some dimensions, but those dimensions are unnecessary in actual assembly. Most tolerance can be relaxed to get a cheap machining process. Our experts will contact with clients to understand the product