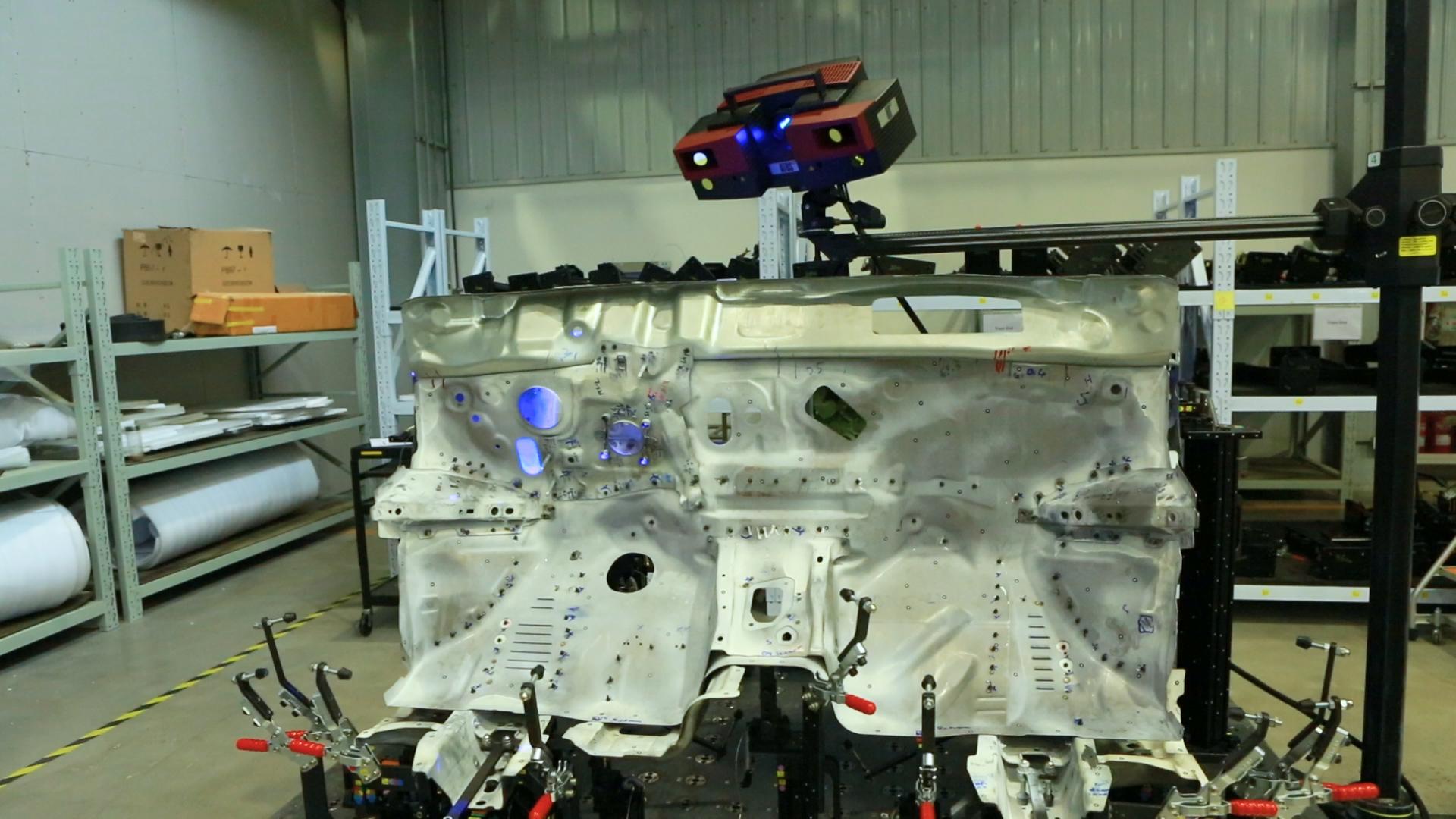

3D scanning is very important machining process in OEM industry, sometime our client only have the physical products but no drawings, then 3D scanner will convert the physical objects into precise digital models in computer. It’s enable you to quickly and accurately capture the details of product. This process bring design engineer with a complete digital representation of part to be used for reverse engineering, quality inspection or at any point of a typical manufacturing cycle.

3D scanning technology can provide customers with:

- Fast, ultra-accurate results, reducing your time to market (saving you time and money!)

- Complete measurement data of the entire surface of your object, verifying that the as-built part matches your CAD model

- True CAD models for FEA testing of actual geometry to correct problems before parts go into production

- CAD models to validate tooling, even when no current models exist

- Profile data of the whole part so assemblies can be digitally put together, revealing inaccuracies and interferences