Carbon Steel ZG230-450

Carbon Steel ZG230-450 in GB/T 11352 for Sand Casting or Lost Wax Precision Investment Casting

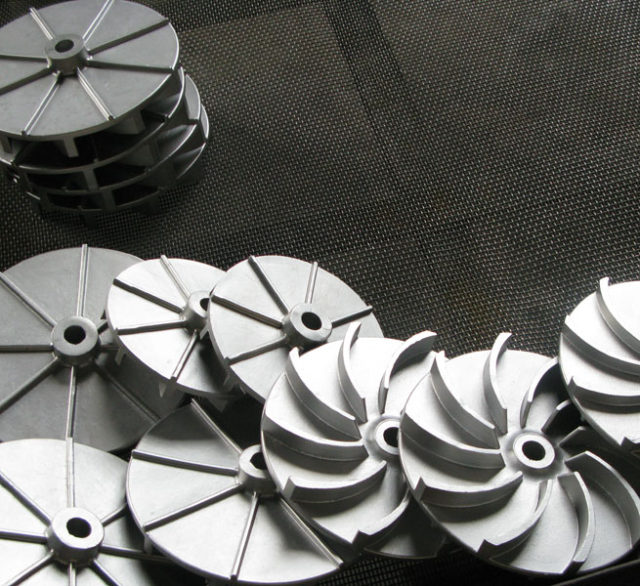

casting Material technology, such as ductile iron, carbon steel, gray iron, stainless steel, malleable iron and alloy.

Carbon Steel ZG230-450 in GB/T 11352 for Sand Casting or Lost Wax Precision Investment Casting

Carbon Steel ZG200-400 in GB/T 11352 for Sand Casting or Lost Wax Precision Investment Casting

Ductile Iron EN-GJS-400-18 is in standard EN1563: 2011, it has EN-GJS-400-18 LT, EN-GJS-400-18 RT and EN-GJS-400-18.

AISI 8620 and AISI8630 are Nickel Molybdenum steel for high strength by investment casting, which contain chromium, nickel and molybdenum. Those two steel grade will be supplied as heat treatment condition. AISI 8620: IC 8620, ASTM A-732 GR 13Q; AS 1444 GR 8620/8620H, EN10084, 1.6523 20NiCrMo2-2; JIS G4103/G4052 SNCM 220; UNS G86200/H86200 AISI 8630: UNS […]

Chrome Nickel Molybdenum Steel AISI 4330/4340 AISI 4330: IC 4330, ASTM A-732 GR 9Q, 10Q, IC 4340

In a low-alloy steel casting, the alloying elements are present in percentages greater than the following: Mn, 1.00; Si, 0.70; Cu, 0.50; Cr, 0.25; Mo, 0.10; V, 0.05; W, 0.05; and Ti, 0.05. Limitations on phosphorus and sulfur contents apply to low-alloy steels as well as carbon steels unless they are specified to be different […]

Carbon Steel ANSI 1030( 2A, 2Q, IC1030), 1040(3A,3Q, IC1040), 1050(4A,4Q, IC1050) in ASTM A732

Carbon Steel 1020 , 1A, IC1020 in ASTM A732

CD3MN is a Fe-Cr-Ni-Mo duplex stainless steel

Stainless steel CF3(SS304L) in ASTM A351, ASTM A743 and ASTM A744 standard.

Duplex Stainless Steel CD4MCu (UNS J93370) in ASMT A351 and ASTM A890

Precipitation-Hardening Stainless Steel CB7CU-1 (17-4PH) in ASTM A747

Carbon Steel WCA in ASTM A216 for casting purpose

ASTM A216 Grade WCB carbon steel for casting purpose, chemistry and mechanical property

Abrasion-Resistant Cast Iron ASTM A532 Class II type A Designation 12% Cr

Stainless Steel CF8 (SS304) in ASTM A743, ASTM A351 and ASTM A744

Stainless Steel include austenitic stainless steel martensitic stainless steel and ferric stainless steel. this material is suitalbe to sand casting and investment casting method. Austenitic steels have austenite as their primary phase

Grey Cast Iron (Gray iron) HT200, HT250, HT300, HT350 in Chinese Standard GB/T 9439

Carbon steel have a good content of carbon, so it is easy to casting. especially A216 WCB. It is important to clarify the meaning of carbon steel in the generic sense and in the more narrow context used in this report. The term steel is usually taken to mean an iron-based alloy containing carbon in […]

Duplex Stainless steel has two phase micro-structure consisting of grains of Ferritic and Austenitic stainless steel. It is mainly used in pump fittings and oil field. Casting Quality Industrial can produce SAF2205 DUPLEX STAINLESS STEEL castings.