Ti-6Al-4V (Grade 5) is the most commonly used titanium alloy, it’s named because of containing 6% aluminum and 4% Vanadium.

Ti-6Al-4V is listed in ISO 5832-3 standard, same as ASTM Grade 5 (UNS R56400) in American standard, Chinese grade is TC4, it’s a two phase (α+β) titanium alloy with good property of tensile and yield strength. It will be good work in 400-500 degree temperature.

Manufacture process: Machined Graphite Mold investment casting, Ceramic Mold Investment Casting.

Melting Temperature: 1538-1649 (2800-3000F) www.castingquality.com

Density: 4.47g/cc (0.160Lbs/cu.)

www.castingquality.com

Grade 5 Titanium Listed in American Standard:

ASTM B265-15 Standard Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate

ASTM B348-13 Standard Specification for Titanium and Titanium Alloy Bars and Billets

ASTM B363-14 Standard Specification for Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings

ASTM B337 – 95 Specification for Seamless and Welded Titanium and Titanium Alloy Pipe (Withdrawn 1997) (REPLACED BY B861 and B862)

ASTM B338-17 Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

ASTM B381 – 13 Standard Specification for Titanium and Titanium Alloy Forgings

ASTM B863 – 14 Standard Specification for Titanium and Titanium Alloy Wire

ASTM F67-13(2017) Standard Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700)

ASTM F136 – 13 Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401)

ASTM B861 – 14 Standard Specification for Titanium and Titanium Alloy Seamless Pipe , pipe, seamless pipe, titanium, titanium alloy, Products and Services

ASTM B862 – 14 Standard Specification for Titanium and Titanium Alloy Welded Pipe , pipe, titanium, titanium alloy, welded pipe,, Products and Services

Our Services

- Sand Casting

Casting Quality focus on Metal Parts industry, we provide professional service in Metal Casting field.

Sand Casting is a popular metal form method, are suitable for all materiel, such as grey iron, ductile iron, malleable iron, carbon steel, stainless steel, aluminum and bronze.

- Investment Casting

also named as precision lost wax casting, mainly suitalbe for carbon steel and stainless steel parts. We also provide grey iron and ductile iron and aluminum and bronze parts by investment casting. It can achieve the best appearance with good tolerance

- Shell Casting

Shell casting method is a good option to replace investment casting and sand casting. the quality is better than sand casting parts, suitable for bulk production.

- CNC Machining

CNC Milling, CNC turning with 5 xix CNC center, we provide precision machining for all castings based on customers design drawings.

- CAD Design

Mechanical Design service based on customers requirement, our software is Solidworks and AutoCAD.

- Tools/Mold Design

Mould design and production will be served for metal casting ad plastic injection industry. Based on our more than 10 years experience, we supply professional molds for our customers in Europe and North American.

Ti-6Al-4V (Grade 5) Titanium Alloy Description

Ti-6Al-4V (Grade 5) Titanium Chemical Requirements:

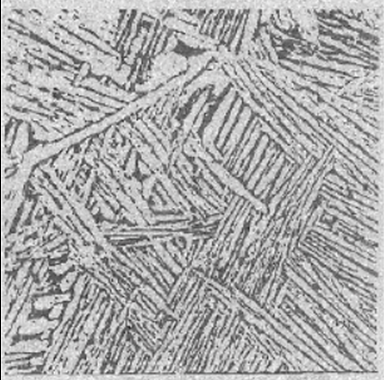

Ti-6Al-4V (Grade 5) Alloy Casting, Cast Condition, 500X

Aluminum: 5.5-6.8

Vanadium: 3.5-4,5

Fe(Iron): 0.3 max

Silicon: 0.15 max

Carbon: 0.1 max

Nitrogen: 0,05 max

Hydrogen: 0,01 max

Others: 0,5 max

Rest: Titanium

www.castingquality.com

Ti-6Al-4V (Grade 5) Titanium Tensile Requirements in ASTM B265:

Tensile Strength, min:130Ksi (895MPa)

Yield Strength, 0.2% offset: 120Ksi(828Mpa)

Elongation in 2in or 50mm, min, %: 10%

Bend Test under 0.070in in thickness: 9T; Bend Test from 0.070 to 0.187in in thickness: 10T

www.castingquality.com

Casting Quality Industrial Provide Ti-6Al-4V (Grade 5) Titanium Castings

Same Titanium alloy in different standard:

| China | ISO | American | Russia | France | Germany | Japan |

| GB/T | ISO | ASTM | TOCT | NF | DIN | JIS |

| TC4 | TiAl6V4 | Grade 5 | BT6 | TA6V | TiAl6V4 | YATB640 |

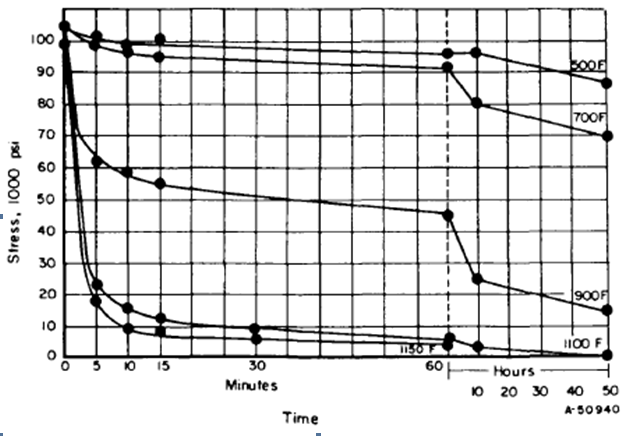

Ti-6Al-4V (Grade 5) Titanium Casting Heat Treatment Process:

- Strength Relief Anneal: at 500-650°C (900 F-1200 F), hold on 1-4 hours, cooling in air. Usually 1 hour in 1100F cooling in air). www.castingquality.com

Effect of Time and Temperature on Stress Relief in Ti-6Al-4V

www.castingquality.com

- Anneal process: 691-850 °C (1300-1550 F), 1-8hours, slowly cooling to 1050F in furnace, then cooling in air.

| Anneal time against thickness | |||||

| Max Thickness, mm | 1.5 | 1.6-2.0 | 2.1-6.0 | 6.0-50 | Above 50 |

| Time, min | 15 | 20 | 25 | 60 | 120 |

- Solution Treatment: 815 -950 °C (1500-1750F), 5 MIN-1hour, water quench.

- Aging Treatment: 485-540°C (900-1000 F), 4-8 hour, cooling in air

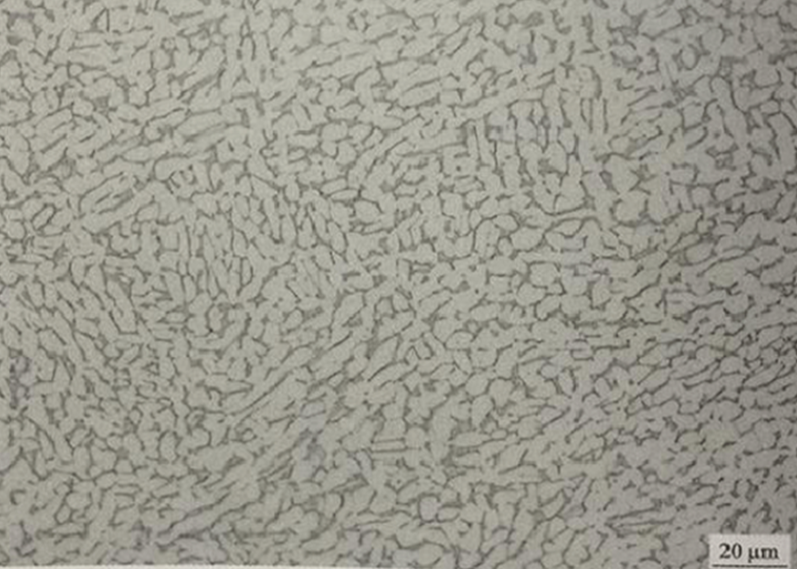

Ti-6-4V (Grade 5) Casting after Anneal Treatment at 800 °C, White α+ Grey β.

Ti-6Al-4V (Grade 5) Titanium Casting Application:

Compressor blades, discs, and rings for jet engines; airframe and space capsule components; pressure vessels; rocket engine cases; helicopter rotor hubs; fasteners.

PDF VIEW

PDF VIEW